Quality improvement begins with standardization. Recently, the group standard T/SZS 4046—2022 "Precious Metal Machine-Woven Chain Jewelry" (hereinafter referred to as the "Standard"), led by Gemhorn Jewelry, successfully passed the review by the Shenzhen Standards Promotion Association and was officially released for implementation. This Standard fills the gap in China's current standardization system for precious metal machine-woven chain jewelry, providing a benchmark for regulating the production and sales of machine-woven chains.

Photo: On-site review by industry experts

Photo: Zhou Peng, Director of Gemhorn's General Office, introducing the Standard's development process

Standardization is the cornerstone of industry development. In recent years, machine-woven chains—the most important category of chain jewelry—have grown rapidly. However, the industry has long lacked clear regulations regarding product classification, naming, quality requirements, and testing methods, resulting in inconsistent and non-standardized practices.

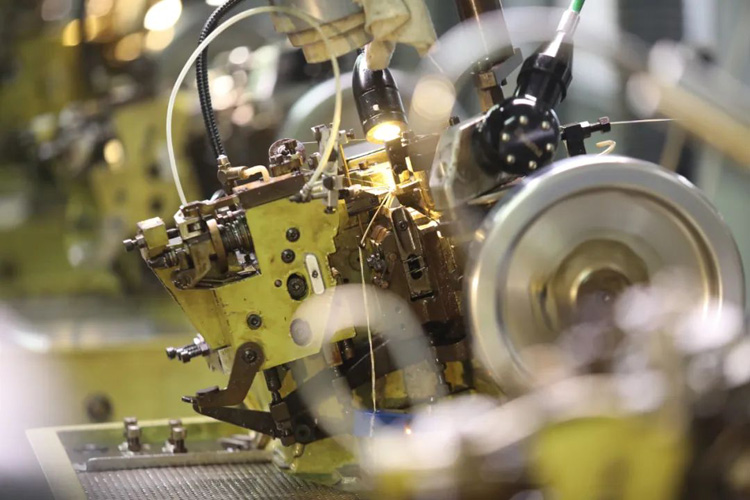

Photo: Gemhorn's machine-woven chain equipment

As a domestic leader in machine-woven chain production, Gemhorn Jewelry established its specialized K-gold factory for machine-woven chains as early as 2005. The factory has invested heavily in thousands of advanced international machines, built multiple world-class automated production lines, and mastered over 400 machine-woven chain designs. With more than 30 national utility model and design patents, it has become the industry's largest and most professional "dream factory" for machine-woven chains. This inherent talent and technological advantage solidified Gemhorn's authority in leading the Standard's formulation.

Photos: Gemhorn's machine-woven chain production line | Precision chain-making machines ensuring high quality

With strong support from the Shenzhen Standards Institute, the Precious Metal & Gemstone Jewelry Enterprise Standards Alliance, and the Shenzhen Gold & Jewelry Association, Gemhorn responded to industry needs by spearheading the Standard's development. Leveraging its expertise, Gemhorn dedicated significant resources to research, testing, and drafting, collaborating with 15 leading industry enterprises—including GMOND, Chow Tai Seng, BaiTai, and Zuan Zhi Yun—to successfully complete the Standard.

The Standard clearly defines terms, appearance quality, performance requirements, testing methods, and product labeling for precious metal machine-woven chains. Addressing consumer concerns about chain breakage, it specifies tensile strength requirements for different materials based on input from manufacturers, retailers, and testing agencies. The Standard is expected to drive innovation across the supply chain, meet consumer demand for high quality, and safeguard their rights.

Moving forward, Gemhorn Jewelry will uphold its commitment to high standards and quality, continuously innovating in R&D, production, and sales while advancing standardization trends in the jewelry industry.

More

One Heart, New Journey | Gemon Group’s 2026 New Year Gala Concludes Successfully!

2026.02.03

GEMHORN Fire Drill Strengthens Safety Defenses, Enhances Full Staff Emergency Response Capability Through Realistic Training

2025.12.04

GEMHORN Joins the Decade-Long "Love Fills Shuibei" Blood Drive with Passion and Dedication!

2025.11.28