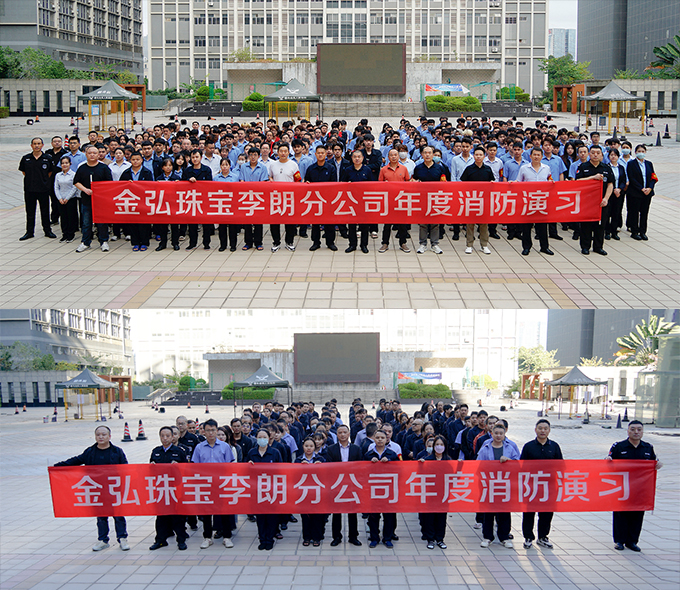

In November 2025, coinciding with the National Fire Safety Awareness Month, GEMHORN Jewelry's various factories successively conducted their annual practical fire drills. This drill adopted a surprise "no-notice, no-preparation" mode, covering critical procedures including fire alarm response, evacuation, casualty rescue, initial fire suppression, personnel accounting, and hands-on operation of firefighting equipment. By simulating sudden fire incidents and reinforcing practical skills, the drill aimed to further enhance employees' emergency self-rescue and coordinated response capabilities, building a solid "firewall" for GEMHORN's safe production.

As the drill officially commenced, a simulated "emergency" occurred within the workshop—a localized fire caused by equipment malfunction, resulting in one employee sustaining a simulated hand injury. At the first sign of danger, the rescue team promptly evacuated and attended to the casualty. Simultaneously, the fire suppression team sprang into action, extinguishing the source of the fire in a timely manner, demonstrating highly efficient emergency coordination.

Following the initial fire response, a simulated secondary fire spread was enacted. Workshop alarms sounded abruptly, initiating the full-staff emergency evacuation phase. Faced with the simulated fire, everyone remained calm and took swift action based on their accumulated safety knowledge: workshop leaders assumed the role of "evacuation guides," organizing an orderly retreat along designated safe routes.

All staff strictly adhered to the escape principles of "keeping to the right, staying low, and crouching." The evacuation proceeded without crowding or panic. Within the critical golden period for fire escape, all personnel successfully reached the designated safe assembly point. A headcount confirmed that no one was left behind, fully demonstrating the effectiveness of routine training.

During the practical skills session, safety officers, considering the specific production environments of each factory and the handling requirements for different types of fires, provided on-site detailed explanations on the applicable scenarios and correct usage methods for smoke hoods, gas masks, dry powder fire extinguishers, and carbon dioxide fire extinguishers.

Smoke hoods and gas masks are life-saving devices in smoky environments and only function effectively when worn correctly. During the hands-on practice, participants worked in groups, repeatedly practicing each step—from unpacking the equipment and adjusting the fit to checking for airtightness—ensuring everyone could complete the donning process quickly and correctly.

In the subsequent fire extinguisher practical session, staff calmly confronted the simulated fire source. Remembering the "P.A.S.S." (Pull, Aim, Squeeze, Sweep) technique for fire extinguisher use, they firmly grasped the extinguisher nozzle with one hand, pressed the handle with the other, and accurately aimed the spray at the base of the fire. Their actions were methodical, standardized, and successfully completed the fire suppression task.

The smooth execution of this practical fire drill fully validated the effectiveness of GEMHORN's emergency response system and showcased the staff's proficient emergency handling and collaboration skills. Moving forward, GEMHORN will continue to adhere to the fire safety principle of "Prevention Before Ignition," integrating safety knowledge into routine training. The company will continuously optimize emergency plans and enhance employees' firefighting skills, embedding safety awareness deeply into every position to safeguard both enterprise production safety and employee lives.

More

One Heart, New Journey | Gemon Group’s 2026 New Year Gala Concludes Successfully!

2026.02.03

GEMHORN Fire Drill Strengthens Safety Defenses, Enhances Full Staff Emergency Response Capability Through Realistic Training

2025.12.04

GEMHORN Joins the Decade-Long "Love Fills Shuibei" Blood Drive with Passion and Dedication!

2025.11.28